The Keys to Successful Field Service Inventory Management

- Published

- 3 min reading

What is field inventory? For companies delivering and installing equipment, field service inventory management is one of the critical aspects of operations. Whether you are an equipment installer or network orchestrator, you need to know where your goods are in real time. It doesn’t matter whether those goods are materials, equipment or spare parts, you should always know who has them, where they are, their current status, and when to maintain them. This knowledge needs to be aggregated in a transparent manner that is easy to verify.

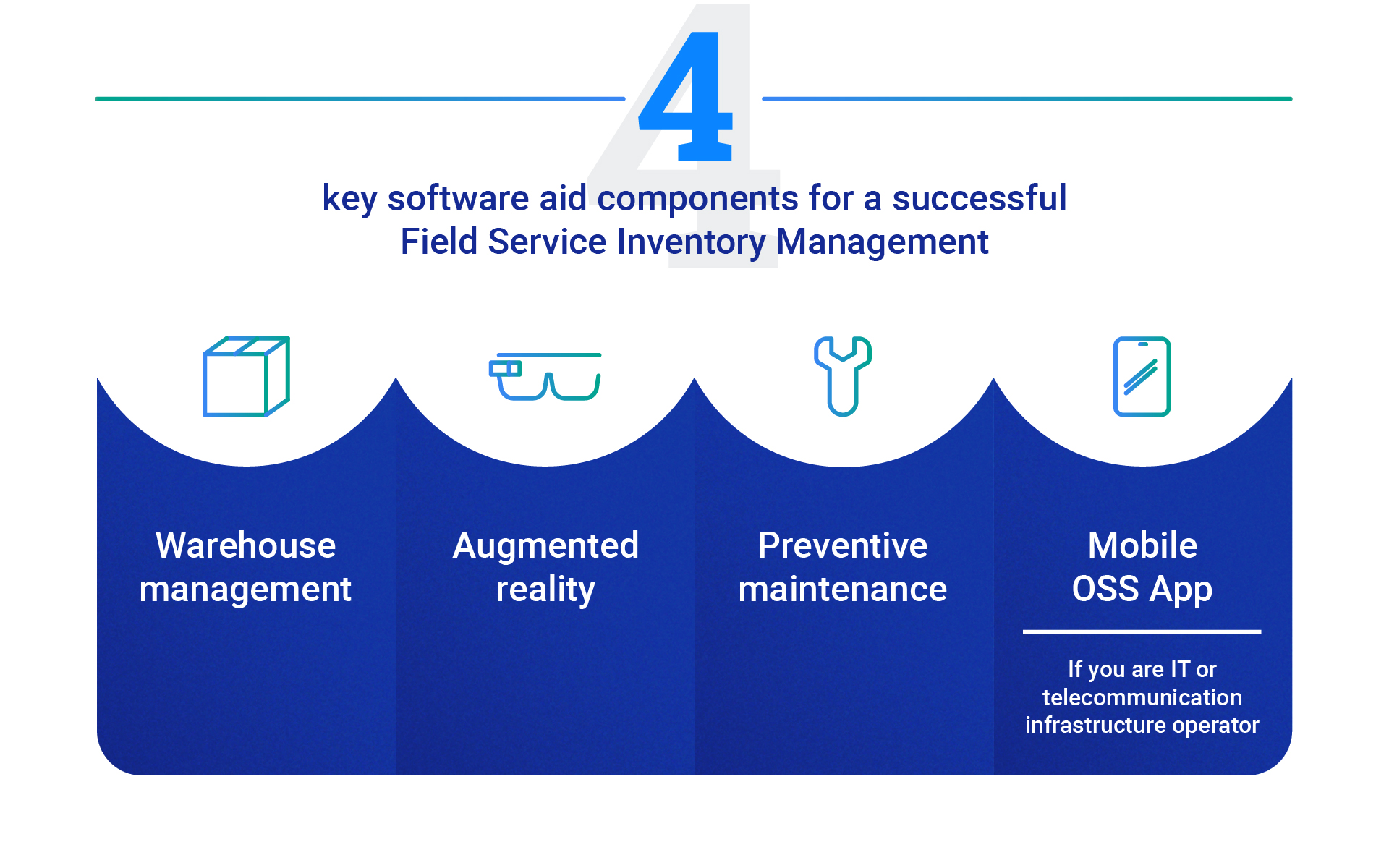

To achieve this, you will need a few software components to be efficiently implemented into your business process.

Field inventory management software – areas in which you can use it

Warehouse management

The heart of field service inventory management is the warehouse management system. It provides dedicated warehouses for each of the field operation parties (the main warehouse, technicians’ trucks, customers and remote sites). The most common flow is that the technician picks up the equipment from the main warehouse, transports it, and installs it at the destination. Workflows that are easy to configure and are governed by an appropriate acceptance process automate the release of equipment and transfer between warehouses.

For each equipment type, the system enables the creation of a specific status flow in order to meet different requirements of the hardware installation process (installing, configuring, provisioning, and so on). Additionally, the tool recognizes precisely which equipment is required to finalize the service request successfully, and which devices should be installed/ uninstalled at the serviced locations. Any equipment-related service requests can be easily dispatched by the system and executed by technicians via a mobile app. Transfers between warehouses are thoroughly tracked according to the workflow, making it easy to control the equipment’s full lifecycle during field operations. Those are the factors that make a successful field technician.

Augmented reality

Modern inventory management solutions coupled with field service management tools provide a wide support for technicians, who carry out installations or maintenance on the site. Augmented reality and QR scanning are among the supporting tools of great importance to the process.

Let's take a look at an example. A technician or sub-contractor receives a request to inspect and troubleshoot a device. While on site, the technician simply points their mobile device at the object to be inspected which is marked with QR codes. Then, the mobile app presents information about the device in augmented reality mode. This information can be quickly obtained on the screen of the technician’s device, and might include such specifications as static machine parameters and links to a knowledge base with instructions or equipment guides. Data might also include real-time dynamic parameters related to the state of the object in question, including alarms or alerts. However, this requires prior configuration with monitoring systems.

Preventive maintenance

An ideal field service inventory management system should also a include a preventive maintenance module, which can help avoid costly failures. The system should allow users to create schedules of preventive maintenance tasks in the context of a site or single piece of equipment. Such tasks include technical reviews, audits and preventive maintenance parts replacement, all of which can help avoid disruption of infrastructure’s normal way of working.

If you are an IT or telecommunication infrastructure operator: mobile OSS app

Efficient task-handling in the rapidly changing 5G environment requires more support and data access for technicians performing field tasks. The OSS Mobile App gives users wide access to the inventory data via a mobile device. Tasks originated in OSS are automatically sent to field staff. A technician or sub-contractor using the OSS Mobile App receives a push notification regarding new tasks in the field inventory management software. To execute the task successfully, the technician needs to be fully familiar with the equipment installed on the site. OSS Mobile App provides technicians with convenient access to inventory data by using:

- Dedicated views for devices and locations object types

- Search filters (vendor, object type, device model, distance from location)

- Map view (with locations)

In addition, the technician can view data which reuse site hierarchy from Comarch OSS. Typically, such information includes:

- Location data (location name, coordinates)

- Site access data (where keys are stored, pin codes to gates, phone numbers to landlords, etc.)

- Site resources: sublocations, devices, connections (network topology)

Technician task realization progress based on statuses (en route, on-site, completed, etc.) is reported back to the OSS BPM module. If the task is finished, the employee simply changes its status to “closed”, which automatically closes that task in Comarch OSS BPM.

Thanks to these four components, you should be able to perform effective and successful field service inventory management and other business processes, either partly or remotely in real-time. As 2020 taught us, this is crucial to the functioning of operations related to field inventory.